Which Structural Steel Shape Fits Your Project? Comparing Beams, Columns, and Channels

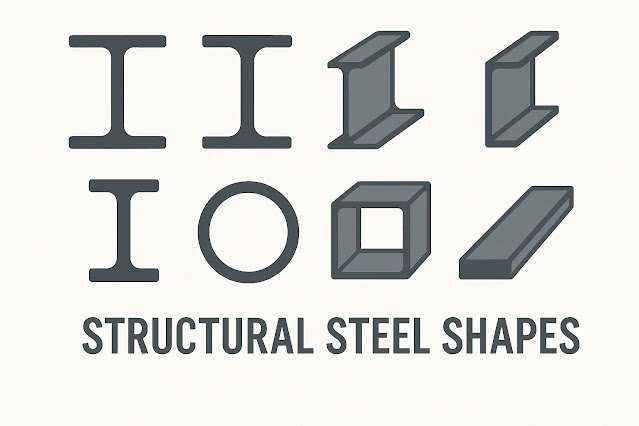

Structural steel shapes are at the heart of most large-scale construction. If you’re planning a project—whether it’s a multi-story office, a warehouse, or a factory—understanding these shapes isn’t optional. The right choice affects not just strength and stability, but also cost and speed. This guide compares the most common steel shapes: beams, columns, and channels. You’ll get details on design, typical uses, and how to pick the best option for your build.

1. Understanding Structural Steel Shapes

Structural steel shapes are engineered pieces of steel designed for use in building frames, bridges, and industrial structures. These shapes come from standard profiles, each with a set width, depth, and thickness, to meet very precise load-bearing needs.

Picking the right shape improves safety, efficiency, and budget. Get this right, and your whole project runs smoother—from design through fabrication and installation. The three heavy-hitters in structural steel construction are beams, columns, and channels.

2. Beams: Overview

|

| Photo by Brett Sayles |

Beams support loads over open spaces. They’re horizontal structural members that transfer weight from floors, roofs, or bridges to columns or walls. Their main job in a steel frame is to fight bending forces from above. Beams get chosen for projects that need clear spans, wide open rooms, or long bridge decks.

Most beams are made from carbon or carbon-manganese steel, chosen for strength, ductility, and cost. They must resist both bending (flexural) and shear forces without excess weight or material waste.

3. Types of Beams

3.1 I-Beams (Wide Flange Beams)

I-beams, also called W-shapes, have flanges (top and bottom horizontal plates) connected by a thin web (vertical plate). This layout creates a strong section that resists bending, while using less steel than a solid rectangle. I-beams often frame floors and roofs, support bridges, and carry other heavy, distributed loads.

3.2 H-Beams

H-beams are similar to I-beams but have wider flanges and thicker webs. The almost-square cross-section gives superior strength for heavy-duty jobs. H-beams are common in building columns, foundations, and key load points in industrial buildings.

3.3 T-Beams

T-beams look like a “T” in cross-section. They’re often created by cutting an I-beam in half. T-beams handle lighter loads and get used as lintels or smaller joists in building frames.

3.4 Other Beam Shapes

- Box Beams: Hollow square or rectangle sections. Good for torsional strength and uniform loads.

- C-Beams (Channel Beams): More on these later, but sometimes serve as beams for light spans or edges.

4. Beam Load Types and Behavior

Beams in structural steel construction support several types of loads:

- Point Loads: Heavy weights on a single spot (like a column above)

- Distributed Loads: Loads spread evenly across the beam (like slabs or roofing)

Beam shape controls how loads travel from the source point, through the web, and out the flanges to supports. The moment of inertia (geometry of the cross-section) determines resistance to bending. Stronger shapes allow longer spans or heavier loads.

Bending moment and shear strength are key. Bending moment is the force trying to bend the beam; shear is the force trying to slide the top of the beam from the bottom. The right beam balances both.

5. Columns: Overview

Columns are the vertical powerhouses of steel frames. They transfer loads from the beams and slabs above down to the foundation. They’re designed to resist compression (getting squashed), and sometimes bending if loads aren’t perfectly centered.

In modern steel construction, columns often use I-sections, HSS (hollow structural sections), or round tubes. The choice depends on the weight to be carried, available space, and how the column connects to the rest of the structure.

6. Types of Columns

6.1 Square and Rectangular Hollow Structural Sections (HSS)

HSS columns are hollow steel tubes with square or rectangular profiles. Closed sections prevent local buckling, making them strong and efficient. These are common in modern offices, warehouses, and high-rise frames.

6.2 Circular Hollow Sections

Round tube columns are used where appearance, torsion resistance, or smooth connection details matter. They’re popular for towers, flagpoles, exposed columns, and architectural frames.

6.3 I-Section Columns

Wide flange or I-section columns handle huge loads with their tall, narrow shape. They’re the standard for multi-story buildings, bridges, and major frames.

6.4 Built-Up Columns

Sometimes, columns are made by welding plates or shapes together for custom sizes or special strength needs. This approach is used for very tall buildings or special load cases.

7. Column Design Considerations

Column success depends on resisting buckling (sideways collapse under stress) and handling axial loads (straight down). The slenderness ratio (length-to-width) drives buckling risk; longer, skinnier columns need bracing.

Column base and connection design is just as important as the column shape. Good bracing keeps loads centered and stable. Poorly designed columns can buckle even under modest loads.

8. Channels: Overview

Channels, or C-sections, have a cross-section shaped like the letter “C”. One side remains open. In steel construction, channels serve as secondary framing, support edges of floors or roofs, and trim out windows, doors, or equipment platforms.

Channels are made from the same steel grades as beams and columns but use less material. Their open profile is great for lighter loads, where cost and ease of use matter most.

Channels can’t handle as much bending or compression as I-beams and columns, but they’re easy to handle and fabricate.

9. Types of Channels

9.1 Standard C-Channels

These have wide flanges and a straight web, making them stable and easy to bolt or weld. They’re used in purlins, girts, edge supports, and bracing.

9.2 U-Channels

Similar to C-channels, but sometimes with a more shallow profile. Used in trim, supports, and lighter frames where deep channels aren’t needed.

9.3 Light vs. Heavy Channels

“Light” channels use thinner steel for less demanding roles. “Heavy” channels have thicker walls and flanges for greater load support.

10. Comparing Beams, Columns, and Channels: Key Factors

Load Types

- Beams: Resist bending, carry distributed and point loads horizontally.

- Columns: Resist axial compression.

- Channels: Handle light loads, mostly in bracing and edge details.

Structural Strength

- Beams: High flexural strength, moderate axial strength.

- Columns: High axial (compression) strength, lower flexural.

- Channels: Moderate to low strength in all directions, more for secondary supports.

Weight and Design Impact

Heavier shapes support more weight but cost more and are harder to install. Lighter channels save money and speed up construction when loads are low.

Fabrication and Installation

Beams and columns often need custom fabrication and skilled welding or bolting. Channels can be cut, drilled, and attached quickly on-site.

11. Shape and Cross-Sectional Geometry

The cross-section determines mechanical properties, especially moment of inertia (bending resistance) and section modulus (strength under load).

- I-beams and H-beams: High moment of inertia, best for spans and heavy loads.

- HSS: Good for axial loads and torsion, smooth sides for architectural uses.

- Channels: Lower moment of inertia, best for lighter, shorter spans.

Section sizes range from a few inches to several feet deep for major builds. Standard charts and tables show exact strengths, weights, and dimensions.

12. Material Efficiency and Cost Considerations

Efficiency matters. Beams and columns use more steel but offer big strength. Channels use less steel and cost less for smaller jobs.

The cost per unit length rises with weight, thickness, and complexity. In structural steel services, using standard shapes and sizes helps control budgets and avoid fabrication delays.

Choosing efficient shapes can trim thousands from a project, especially over long spans or high stories.

13. Practical Applications with Shape Recommendations

When to Choose Beams

For long, open spans like warehouses, gymnasiums, or bridges, pick beams. They support floors, roofs, and road decks with strength and stability. Residential and commercial projects use beams as floor and roof joists, girders, and headers.

When to Choose Columns

Use columns for vertical load paths—multi-story buildings, towers, parking garages, and industrial frames. They’re key where heavy loads stack up from top to bottom.

When to Choose Channels

Channels are perfect for non-critical tasks. They act as side rails, short-span joists, window or door frames, or light industrial supports. You’ll spot channels in roof edge trims, wall girts, purlins above open bays, and machinery bases. In automotive and equipment frames, their open side allows easy connections and custom brackets.

14. Installation and Fabrication Differences

Beams and columns often call for skilled fabrication. Precision cuts, holes, and welds keep frames true and strong. Wide flanges on beams and columns allow for easy bolting and welding, though their weight demands lifting equipment and careful planning.

Channels are lighter and simpler to cut and drill on-site. Their open shape means you can attach them to concrete, wood, or steel quickly—great for field adjustments.

Transport is a breeze for lighter channels but needs planning for long or heavy beams and columns. Handling strategies can affect your timeline and labor costs.

15. Advantages and Disadvantages

Beams

Pros:

- High bending and shear strength

- Ideal for long spans

- Multiple profiles and sizes for any project

Cons:

- Heavier, more costly per foot

- Needs careful bracing for stability

Columns

Pros:

- Best for compressive (axial) loads

- Available in many profiles (HSS, I-sections, etc.)

- Can be custom-built for huge loads

Cons:

- Vulnerable to buckling if not braced well

- May require fireproof coatings

Channels

Pros:

- Lightweight, easy to handle and install

- Cost-effective for secondary work

- Simple connections

Cons:

- Low bending and compression strength

- Not suitable for long spans or heavy loads

16. Standards and Codes to Consider

Structural steel shapes must meet recognized standards from bodies like ASTM and the American Institute of Steel Construction (AISC). These codes govern shape dimensions, steel strength, fabrication quality, and safety. Following these standards during detailing and construction isn’t just best practice—it’s required by law for most jobs.

17. Shape Selection Examples

Project 1: Steel Warehouse

- Uses wide-flange beams for open floor spans.

- Square HSS columns line the perimeter and interior.

- Channels support the roof deck and edge trims.

Project 2: Office Tower

- Heavy I-beams frame each floor.

- Built-up columns carry the vertical weight.

- Channels reinforce window frames and elevator bays.

Project 3: Machinery Platform

- Channels make up the service walkways.

- I-beams support major equipment.

- Circular HSS columns for clean looks and torsion support.

18. Summary Table: Comparing Beams, Columns, and Channels

| Feature | Beams | Columns | Channels |

|---|---|---|---|

| Main Load Type | Bending/Shear | Compression | Light/Edge |

| Typical Section | I, H, T, Box | HSS, I, Built-up | C/U |

| Strength | High (bending) | High (axial) | Moderate |

| Weight/Cost | High | Moderate-High | Low |

| Uses | Spanning | Vertical support | Bracing, edges |

| Fabrication | Moderate-Complex | Moderate-Complex | Simple |

19. Frequently Asked Questions

Can beams be used as columns?

Wide-flange (I or H) sections can serve as columns, but only if sized for compression and buckling. Always check design codes.

Are channels suitable for load-bearing walls?

Not for primary support—channels are too weak. Use beams or columns for heavy loads.

What shape is best for long spans?

I-beams (wide flange) and box beams are standard. Size is based on span length and load.

How do I know what size to use?

Consult with a structural engineer or use digital tools based on codes like AISC ASD/LRFD. Detailers and steel services providers can also guide you using up-to-date tables.

20. Additional Resources

- AISC Steel Construction Manual

- Steel Shape Dimension Charts

- Software: SkyCiv Structural Analysis, ETABS

- For steel shape standards: ASTM Standards

21. Glossary of Key Terms

- Flange: The flat horizontal part of a beam or column cross-section.

- Web: The vertical center section connecting the flanges.

- Moment of Inertia: A measure of a shape’s resistance to bending.

- Section Modulus: A value showing how strong a shape is under bending force.

- Buckling: Failure of a column by sideways bending under compression.

- Purlin/Girt: Horizontal members used in roofs/walls, often channels.

22. Troubleshooting Common Issues

- Improper Shape Selection: Can cause sagging, buckling, or failure. Always align the shape with expected loads and follow standards.

- Undersized Beams: Lead to excessive deflection or even collapse.

- Under-braced Columns: Prone to buckling, especially as height increases.

- Using Channels for Main Spans: Often results in weak, flexible frames—use beams for main supports.

23. Future Trends in Structural Steel Shapes

The structural steel shapes market is growing fast, projected to reach $169.6 billion by 2032. There’s a shift to high-strength, low-carbon steels and more pre-fab, modular steel shapes for quicker builds and less waste. New standards from AISC and ASTM push performance up and keep projects safer. As construction gets smarter and greener, shape selection is more important than ever.

24. Conclusion

Choosing the right structural steel shape shapes your project’s success. Beams span space, columns carry loads, and channels fill in the gaps. Each has clear strengths, best uses, and cost implications. By understanding these profiles and working with professional steel detailing services, your project will be strong, efficient, and up to code. Smart selection keeps your building standing—for the long haul.

If you’re starting a project, always consult with your engineer or trusted structural steel services provider. Their expertise, backed by the right shapes, makes all the difference in safe, cost-effective construction.

0 Comments