Introduction:

Custom steel fabrication is a process that involves the creation of steel products that are tailored to the specific needs of a business or organization. From buildings and bridges to aircraft and machinery, custom steel fabrication can be used to produce a wide range of products that meet unique specifications. In this post, we will explore the basics of custom steel fabrication, the benefits of the process, the applications of custom steel fabrication in different industries, and how to choose the right custom steel fabricator for your project. By the end of this guide, you will have a better understanding of how custom steel fabrication can benefit your business and how to select the right fabricator to meet your needs.

Section 1: What are Custom Steel Fabricators?

Custom steel fabricators are companies that specialize in producing steel products for various industries. They use different steel fabrication processes such as cutting, bending, and welding to create complex structures that meet specific requirements. The steel products produced by custom steel fabricators can range from small components to large structures such as bridges, skyscrapers, and industrial plants.

Custom steel fabricators offer several benefits over off-the-shelf products. Firstly, they can create high-quality products that meet exact specifications. This is particularly important in industries where safety is a concern or where there are strict regulatory requirements. Secondly, custom steel fabricators are often able to meet tight deadlines and work on complex projects that require specialized skills and expertise. Thirdly, using custom steel fabricators can often reduce costs, especially for large or complex projects, as they can streamline the production process and minimize waste.

There are different types of steel fabrication processes that custom steel fabricators use, depending on the project's requirements. These can include:

Cutting: Custom steel fabricators use different cutting techniques such as laser cutting, plasma cutting, and waterjet cutting to cut steel sheets or plates into the required shapes.

Bending: Custom steel fabricators use different bending techniques such as press brakes, rollers, and hammers to bend steel sheets or plates into the required angles and shapes.

Welding: Custom steel fabricators use different welding techniques such as MIG, TIG, and stick welding to join steel components together to create larger structures.

Machining: Custom steel fabricators use different machining techniques such as drilling, milling, and turning to create precise holes, threads, and shapes on steel components.

Using custom steel fabricators offers several benefits for different industries, such as construction, aerospace, automotive, and manufacturing. They can produce products that meet exact specifications, reduce costs, and increase efficiency.

Section 2: How to Choose the Right Custom Steel Fabricator for Your Project

Choosing the right custom steel fabricator is crucial to the success of any project. There are several factors to consider when selecting a custom steel fabricator, such as their experience, capabilities, certifications, and reputation. Here are some tips to help you choose the right custom steel fabricator for your project:

Experience: Look for a custom steel fabricator that has extensive experience in your industry and with similar projects. Ask for their portfolio or case studies to see their previous work and projects.

Capabilities: Consider the fabricator's capabilities, such as their equipment, materials, and production capacity. Ensure that they have the required equipment and skills to produce the steel products you need.

Certifications: Check if the custom steel fabricator has the necessary certifications and qualifications, such as ISO 9001, AWS, or ASME. These certifications ensure that the fabricator meets certain standards and quality requirements.

Reputation: Look for reviews or testimonials from previous clients to gauge the fabricator's reputation. You can also ask for references and contact their previous clients to get feedback on their experience working with the fabricator.

Communication: Communication is essential in any project. Ensure that the custom steel fabricator has good communication skills and is responsive to your inquiries and concerns.

Collaboration: Collaboration between you and the fabricator is crucial to the success of the project. Ensure that the fabricator is open to your ideas and suggestions and is willing to work with you throughout the project.

Choosing the right custom steel fabricator can make a significant difference in the success of your project. By considering the factors above and selecting a fabricator that meets your requirements, you can ensure that your project is completed on time, within budget, and to the desired quality standards.

|

| Photo by Magda Ehlers |

Section 3: Benefits of Using Custom Steel Fabricators

Custom steel fabricators offer several benefits over off-the-shelf steel products. Here are some advantages of using custom steel fabricators:

High-quality products: Custom steel fabricators use high-quality materials and advanced fabrication techniques to produce products that meet strict quality standards. They can also provide additional services such as testing and inspection to ensure that the products meet your specifications.

Tight deadlines: Custom steel fabricators are equipped to handle tight deadlines and fast turnaround times. They can adjust their production schedules to meet your project timelines and ensure that the products are delivered on time.

Customization options: Custom steel fabrication offers a wide range of customization options, such as size, shape, finish, and design. This allows you to tailor the products to your specific requirements and achieve your project goals more efficiently.

Reduced costs: Custom steel fabrication can be more cost-effective than using off-the-shelf steel products. By optimizing the design and production process, custom steel fabricators can reduce material waste, improve efficiency, and lower costs.

Expertise and support: Custom steel fabricators have extensive knowledge and expertise in steel fabrication and can provide valuable support and advice throughout the project. They can also offer design and engineering services to help you optimize the products for your specific application.

Custom steel fabrication offers several advantages over off-the-shelf steel products. By using a custom steel fabricator, you can ensure that your products are of high quality, delivered on time, and tailored to your specific requirements.

Section 4: Applications of Custom Steel Fabrication

Custom steel fabrication is used in various industries, such as construction, aerospace, automotive, and manufacturing. Here are some applications of custom steel fabrication:

Construction: Custom steel fabrication is commonly used in the construction industry for building structures, such as bridges, buildings, and stadiums. Steel's strength, durability, and versatility make it an ideal material for construction projects.

Aerospace: Custom steel fabrication is used in the aerospace industry for manufacturing aircraft and spacecraft components. Steel's lightweight and corrosion-resistant properties make it an ideal material for these applications.

Automotive: Custom steel fabrication is used in the automotive industry for manufacturing parts and components, such as frames, bodies, and engine parts. Steel's strength, durability, and cost-effectiveness make it a popular material in the automotive industry.

Manufacturing: Custom steel fabrication is used in the manufacturing industry for producing a wide range of products, such as machinery, equipment, and tools. Steel's strength, durability, and versatility make it an ideal material for these applications.

Here are some specific examples of custom steel fabrication projects in different industries:

Construction: The Golden Gate Bridge in San Francisco, California, is a famous example of custom steel fabrication in the construction industry. The bridge's steel cables and towers were fabricated specifically for this project.

Aerospace: The Boeing 747 aircraft uses custom steel fabrication for its structural components, such as the wings and fuselage.

Automotive: The Ford F-150 truck uses custom steel fabrication for its frame and body components, which are designed to be durable and withstand heavy use.

Manufacturing: The steel industry itself relies heavily on custom steel fabrication for producing various steel products, such as pipes, sheets, and rods.

Custom steel fabrication is a versatile and widely-used process that is applied in various industries. By leveraging the benefits of custom steel fabrication, businesses can produce high-quality, durable, and cost-effective products that meet their specific requirements.

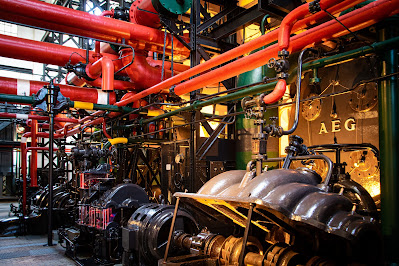

|

| Photo by Pixabay |

Section 5: Choosing the Right Custom Steel Fabricator

Choosing the right custom steel fabricator is crucial to the success of your project. This section will provide guidance on how to select the right custom steel fabricator for your project. We will discuss the factors to consider when choosing a custom steel fabricator, such as their experience, capabilities, certifications, and reputation. We will also highlight the benefits of working with a reputable and experienced custom steel fabricator.

Experience: When selecting a custom steel fabricator, it is important to consider their experience in the industry. Look for fabricators that have a proven track record of delivering high-quality products and services. An experienced fabricator will have the necessary knowledge and expertise to handle complex projects and provide valuable advice throughout the process.

Capabilities: Consider the capabilities of the custom steel fabricator you are considering. Look for a fabricator that has the necessary equipment, facilities, and personnel to handle your project. A fabricator with advanced equipment and facilities will be better equipped to produce high-quality products efficiently.

Certifications: Check if the custom steel fabricator has relevant certifications, such as ISO 9001, ASME, or AWS. These certifications indicate that the fabricator meets strict quality and safety standards and has a commitment to continuous improvement.

Reputation: Look for a custom steel fabricator with a strong reputation in the industry. Check reviews and testimonials from previous clients to get an idea of their level of customer satisfaction. A reputable fabricator will prioritize customer service and ensure that the products meet the client's expectations.

Benefits of working with a reputable and experienced custom steel fabricator: By working with a reputable and experienced custom steel fabricator, you can ensure that your project is in good hands. A reputable fabricator will provide valuable support and advice throughout the process, deliver high-quality products on time, and ensure that the products meet your specific requirements.

Choosing the right custom steel fabricator is essential for the success of your project. By considering the fabricator's experience, capabilities, certifications, reputation, and the benefits of working with a reputable and experienced fabricator, you can ensure that your project is completed to the highest standards.

Section 6: Conclusion

Custom steel fabrication is an essential process for businesses that require high-quality, durable, and cost-effective steel products. By leveraging the benefits of custom steel fabrication, businesses can produce products that meet their specific requirements and achieve their goals. In this post, we have discussed the basics of custom steel fabrication, the benefits of the process, the applications of custom steel fabrication in different industries, and how to choose the right custom steel fabricator for your project.

We have highlighted the various advantages of custom steel fabrication, such as the ability to produce unique and complex shapes, the strength and durability of the material, the ability to produce products in large quantities, and the cost-effectiveness of the process. These benefits make custom steel fabrication an attractive option for businesses that require high-quality steel products.

We have also discussed the various applications of custom steel fabrication in different industries, such as construction, aerospace, automotive, and manufacturing. Custom steel fabrication is a versatile process that can be used in various industries to produce different products, ranging from buildings and bridges to aircraft and machinery.

Lastly, we have provided guidance on how to choose the right custom steel fabricator for your project. We have discussed the factors to consider when selecting a custom steel fabricator, such as their experience, capabilities, certifications, and reputation. By working with a reputable and experienced custom steel fabricator, businesses can ensure that their project is completed to the highest standards.

In conclusion, custom steel fabrication is an essential process for businesses that require high-quality steel products. By understanding the benefits of custom steel fabrication, the applications of the process in different industries, and how to choose the right custom steel fabricator for your project, businesses can produce products that meet their specific requirements and achieve their goals.

0 Comments