In this section, the author will provide the reader with a guide to different types of drawings that are produced in a steel shop.

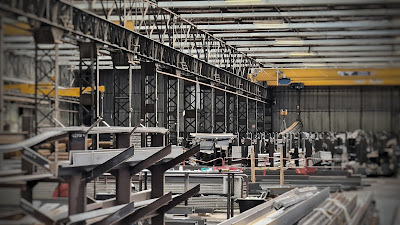

Introduction: A steel shop drawing is an engineering drawing that shows the layout of steelwork on which fabrication of structural steel products is based. Steel shops use these drawings to set up their equipment for cutting and welding steel plates, beams, and other structural materials into finished products.

The steel shop drawings are used to provide information about the steel components that will be fabricated in the fabrication shop. The fabrication shop drawings are used to provide information about the sheet metal components that will be fabricated in the fabrication shop.

Steel shop drawings and fabrication drawings are similar but they serve different functions, depending on who is using them.

This article provides a complete guide to both kinds of drawings, with tips for producing them accurately and efficiently.

The main difference between steel shop drawing and fabrication drawing is that steel shop drawing only needs to provide information about steel components, while fabrications drawing can also provide information about sheet metal components. Fabrication drawings usually include more detail than steel shop drawings because they need to be able to produce accurate cuts for accurate production of parts later, which is essential in many manufacturing processes.

Introduction: What is a Steel & Fabrication Shop Drawing and How Does it Work?

Steel and fabrication shop drawings are drawings that are used to create a blueprint for steel or metal to be manufactured. These drawings show the layout of the piece, dimensions, specification of the material, welding details, where it is cut at, and anything else that might be needed to produce it.

The purpose of these drawings is to provide an accurate depiction of how a piece will be made so that when it is manufactured and completed, there is no confusion about how it should look.

These diagrams include:

- The different types of steel or metal needed to complete the project

- A list of all necessary equipment and tools

- Any specific instructions related to welding

- Dimensions

- How pieces such as brackets will be attached

What is Inside a Steel or Fabrication Shop Drawing?

The drawing tells people what they are building and how to assemble it.

It will contain all the necessary information about the project, including measurements, materials needed, and detailed instructions for assembling the project.

This type of drawing is commonly used in steel fabrication plants and fabricator shops to show what they are constructing for their clients.

There are often drawings of each part on each page with dimensions.

Engineers use these drawings to make sure that all of the pieces will fit together when they’ve finished putting them together.

Steel and Fabrication drawings are not as easy to read as we think. There are some basic rules that you need to know before you start reading and interpreting them.

Drawings can be used for many purposes: accounting, engineering, and fabrication. Drawings of steel structures are different from those of fabrications, but they make use of some common elements.

How to Read a Steel or Fabrication Shop Drawing with the Proper Perspective

With the right knowledge, anyone can read a plan drawing. You don't need any prior experience in engineering or drafting.

The best way to learn how to read a plan drawing is by doing exercises using various drawings. Each time you get better at deciphering the intricacies of the drawings, you can move on to more challenging exercises.

This article will share several blueprint reading exercises that are helpful for beginners and experienced architects alike, so they can get acquainted with this type of drawing and improve their skills in deciphering them.

The first step to reading a steel or fabrication shop drawing is to understand and remember that the plan is drawn with architectural or engineering conventions. This means that the "up" on the plan is not always straight up and down as we might see in a construction project. Steel and fabrication drawings are drawn with their "up" parallel to the horizon.

The second step to reading a steel or fabrication shop drawing is also remembering that it might be confusing at first glance. While there are no specifiers in the title blocks, there are symbols throughout that tell you what type of project it covers—i.e., industrial, commercial, residential, etc. The third step would be to identify symbols—some of which can be found in any blueprint book—that will help you figure out what piece of equipment to purchase.

How do you Prepare for a Day of Reading Blueprints and Making Plans in the Workshop?

A workshop day can be broken up into three parts:

1. Planning - how the projects are going to be completed

2. Reading blueprints - reading plans and instructions for what needs to be done

3. Making Plans - following the instructions and completing the project

There are a few questions that need to be answered before starting work on any project in a workshop:

- What are your goals?

- What materials do you have at your disposal?

- What is your plan of attack?

- Which skills do you need to complete this task?

Conclusion: Start Building the Structural Steel Foundation of Your Project Today With Blueprint

A blueprint can seem like a plan for a building that is in the future, but the truth is that it is a plan for today. A blueprint's purpose is to tell you exactly how to create your project in the desired form and with the desired materials.

With a blueprint, you don’t have to worry about any of the details of your project. You know how it will be built and what it will look like when completed.

In this way, blueprints are tools of both planning and execution. They allow you to complete your projects from start to finish with precision and efficiency while staying on budget and schedule.

Conclusion: With Blueprint, you can be sure that your future projects will be planned accurately from beginning to end so that they stay on schedule and within budget.

0 Comments