🔌Table of Contents

- 1. The Manufacturing Process of Structural Steel Beams

- 2. What are Steel I Beams?

- 3. Types of Steel I Beams

- 4. Applications of Structural Steel Beams and Steel I Beams

- 5. Advantages of Structural Steel Beams and Steel I Beams

- 6. Limitations and Considerations

- 7. Frequently Asked Questions (FAQs)

- 8. Conclusion

Introduction

Structural steel beams are the backbone of modern construction, providing strength and support to various types of structures. Among the most common and versatile types of steel beams are Steel I Beams, which boast an impressive combination of strength, stability, and cost-effectiveness. In this comprehensive guide, we'll explore the ins and outs of structural steel beams and steel I beams, from their manufacturing process to their various applications, benefits, and limitations. We'll also address frequently asked questions and conclude with a summary of key takeaways.

1. The Manufacturing Process of Structural Steel Beams

1.2 Rolling Process

In the rolling mill, the steel billets, blooms, or slabs are heated and passed through a series of rollers that gradually shape the steel into the desired profile, such as an I beam, H beam, or other structural shapes. The steel is then cooled, cut to length, and straightened before being subjected to various tests and inspections to ensure quality and compliance with industry standards.

1.3 Surface Treatments

Depending on the intended application and environment, structural steel beams may undergo surface treatments to enhance their durability and resistance to corrosion. These treatments can include hot-dip galvanizing, painting, or the application of protective coatings.

2. What are Steel I Beams?

Steel I beams, also known as H-beams or universal beams, are structural steel members with an I-shaped cross-section. The I shape consists of a central vertical web flanked by horizontal flanges on the top and bottom. This configuration offers high resistance to bending and torsion, making I beams an ideal choice for supporting loads in various types of structures.

2.2 Materials and Grades

Steel I beams are typically made from mild steel or high-strength, low-alloy steel (HSLA). The choice of material and grade depends on the specific requirements of a project, such as load-bearing capacity, environmental conditions, and budget. Common steel grades for I beams include ASTM A36, A572, A992, and A588.

|

| Image by Foundry Co from Pixabay |

2.3 Standard Dimensions

Steel I beams are available in a wide range of standard dimensions, which are defined by the depth (height) of the beam, the width of the flanges, and the thickness of the web and flanges. These dimensions are specified by industry standards such as the American Institute of Steel Construction (AISC) and the European Committee for Standardization (CEN).

3. Types of Steel I Beams

Standard I beams, also known as S-beams, have relatively narrow flanges compared to their depth. They are most commonly used for residential and light commercial construction, as well as smaller-scale infrastructure projects.

3.2 Wide Flange Beams

Wide flange beams, or W-beams, have flanges that are significantly wider than their depth. This design offers greater load-bearing capacity and resistance to bending, making them well-suited for larger-scale construction projects, such as commercial and industrial buildings, as well as heavy-duty infrastructure projects.

3.3 Bearing Pile Beams

Bearing pile beams, or H-piles, are designed specifically for deep foundation applications. They have a robust cross-section that offers high load-bearing capacity and excellent resistance to lateral forces, making them ideal for supporting structures such as bridges, skyscrapers, and large industrial complexes.

4. Applications of Structural Steel Beams and Steel I Beams

In building construction, steel I beams are used as primary load-bearing members for walls, floors, and roofs. They are an integral component of steel framing systems, providing strength and stability to the overall structure. They can also be used to create long spans and open floor plans, which are popular in modern architecture.

4.2 Bridge Construction

Steel I beams are widely used in the construction of bridges due to their high strength-to-weight ratio and resistance to corrosion. They can be found in various components of a bridge, such as the deck, superstructure, and substructure, and can be used in conjunction with other materials, such as concrete, to create composite bridge systems.

4.3 Industrial Applications

In industrial settings, steel I beams are often used to construct support structures for equipment, machinery, and storage facilities. They can also be found in crane systems, conveyor systems, and mezzanines, providing strength and stability to these essential components.

4.4 Infrastructure Projects

Steel I beams are a popular choice for a variety of infrastructure projects, including highway and railway overpasses, utility towers, and retaining walls. Their high load-bearing capacity, durability, and ease of installation make them a cost-effective solution for these critical applications.

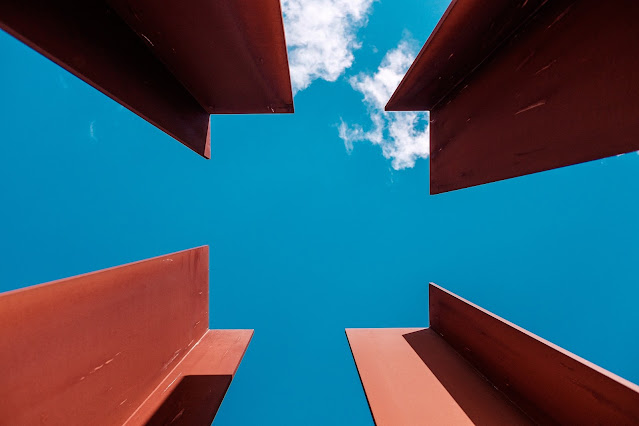

4.5 Architectural Structures

In addition to their functional role in supporting loads, steel I beams can also be used as a design element in architectural structures. Exposed steel beams can add an industrial aesthetic to a building or serve as a focal point in a space.

|

| Image by rjornal from Pixabay |

5. Advantages of Structural Steel Beams and Steel I Beams

Structural steel beams, particularly steel I beams, offer exceptional strength and durability. Their high strength-to-weight ratio allows them to support large loads while remaining relatively lightweight, making them an ideal choice for a wide range of applications.

5.2 Design Flexibility

Steel I beams can be easily customized to meet the specific requirements of a project, such as load-bearing capacity, span, and connection methods. They can also be easily modified on-site, allowing for greater design flexibility and adaptability.

5.3 Speed of Construction

The use of steel I beams in construction can significantly reduce construction timelines, as they can be quickly fabricated and installed on-site. This not only helps to lower overall construction costs but also minimizes disruptions to the surrounding environment.

5.4 Cost-Effectiveness

While the initial cost of steel I beams may be higher than alternative materials, their long-term benefits, such as reduced maintenance and increased longevity, make them a cost-effective choice for many applications.

5.5 Sustainability

Structural steel beams, including steel I beams, are an environmentally friendly choice, as they can be easily recycled and repurposed at the end of their life cycle. Additionally, the use of steel I beams can help to reduce the overall carbon footprint of a project due to their high strength-to-weight ratio and reduced construction timelines.

6. Limitations and Considerations

While steel I beams are highly resistant to corrosion, they are not immune to it. To ensure the long-term durability and performance of steel I beams, proper protection measures, such as galvanizing, painting, or the application of protective coatings, must be employed.

6.2 Fire Resistance

In the event of a fire, steel I beams can lose their structural integrity, leading to potential structural failures. Therefore, it is crucial to incorporate fire-resistant materials and protective coatings in the design and construction process to mitigate these risks.

6.3 Connection Considerations

The connection methods used to join steel I beams play a crucial role in the overall stability and performance of a structure. Connection methods, such as bolting, welding, or riveting, must be carefully selected and executed to ensure the integrity of the connections and the load-bearing capacity of the beams.

|

| Image by Foundry Co from Pixabay |

7. Frequently Asked Questions (FAQs)

Steel I beams and H beams are essentially the same structural elements with an I-shaped cross-section. The terms are often used interchangeably, but H beams typically have a wider flange width, making them better suited for larger-scale projects with higher load-bearing requirements.

7.2 How do I choose the right size of steel I beam for my project?

Selecting the appropriate size of steel I beam depends on factors such as the span, load, and environmental conditions of the project. Consulting with a structural engineer or utilizing beam-sizing calculators can help to determine the correct size for your specific application.

7.3 How do I calculate the load-bearing capacity of a steel I beam?

Calculating the load-bearing capacity of a steel I beam requires knowledge of the beam's dimensions, material properties, and the specific loads and forces acting upon it. A structural engineer can help to determine the load-bearing capacity by analyzing these factors and applying relevant engineering principles and codes.

7.4 Can steel I beams be used in residential construction?

Yes, steel I beams are commonly used in residential construction, particularly in steel framing systems and as support for long spans in open floor plans.

7.5 What are the alternatives to steel I beams?

Alternatives to steel I beams include wood beams, laminated veneer lumber (LVL) beams, and reinforced concrete beams. The choice of an alternative material depends on factors such as budget, design preferences, and project-specific requirements.

8. Conclusion

As we've explored in this comprehensive guide, structural steel beams, particularly steel I beams, are essential components in modern construction. They provide unmatched strength, stability, and cost-effectiveness for a wide range of applications, from building and bridge construction to industrial and infrastructure projects. However, they are not without their limitations, and careful consideration must be given to factors such as corrosion, fire resistance, and connection methods.Whether you're a professional in the construction industry, an architect, or simply a curious reader, we hope that this guide has provided valuable insights into the world of structural steel beams and steel I beams. If you have any further questions or require additional information, please consult the resources and references provided throughout this article.

0 Comments